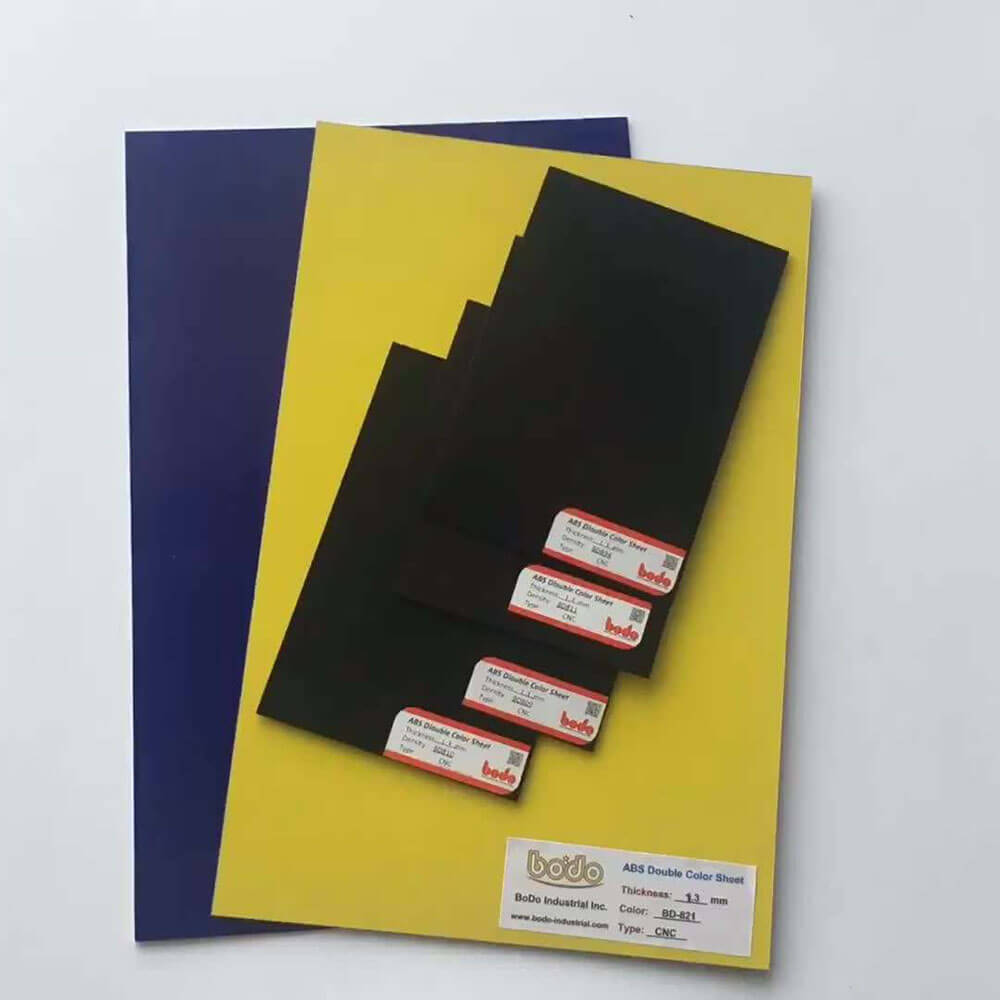

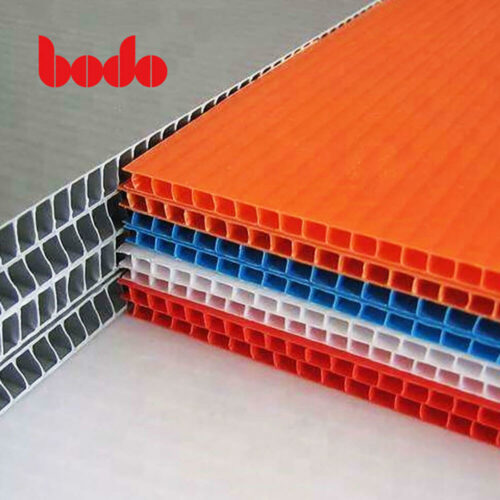

ABS (Acrylonitrile Butadiene Styrene) plastic sheet is a thermoplastic polymer that is known for its strength, rigidity, and durability. It is a widely used material in the manufacturing industry due to its excellent properties, making it an ideal choice for a range of applications.

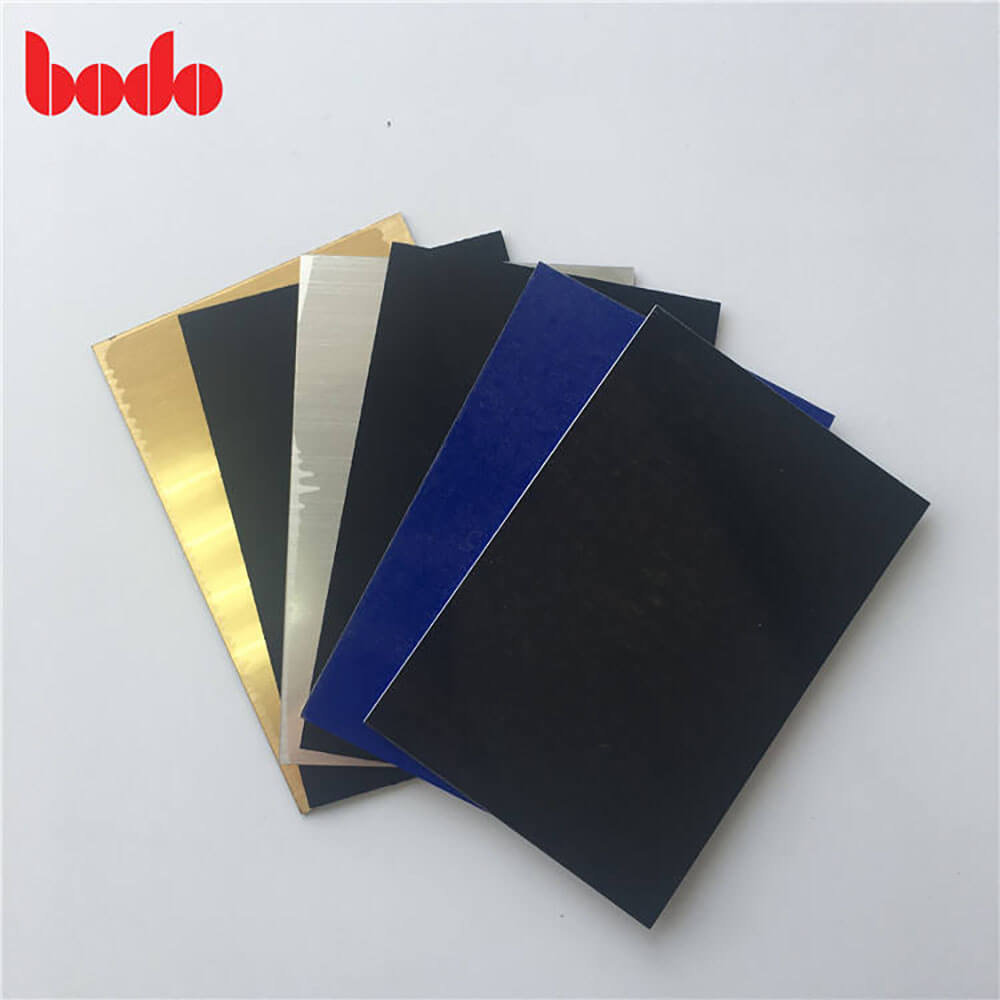

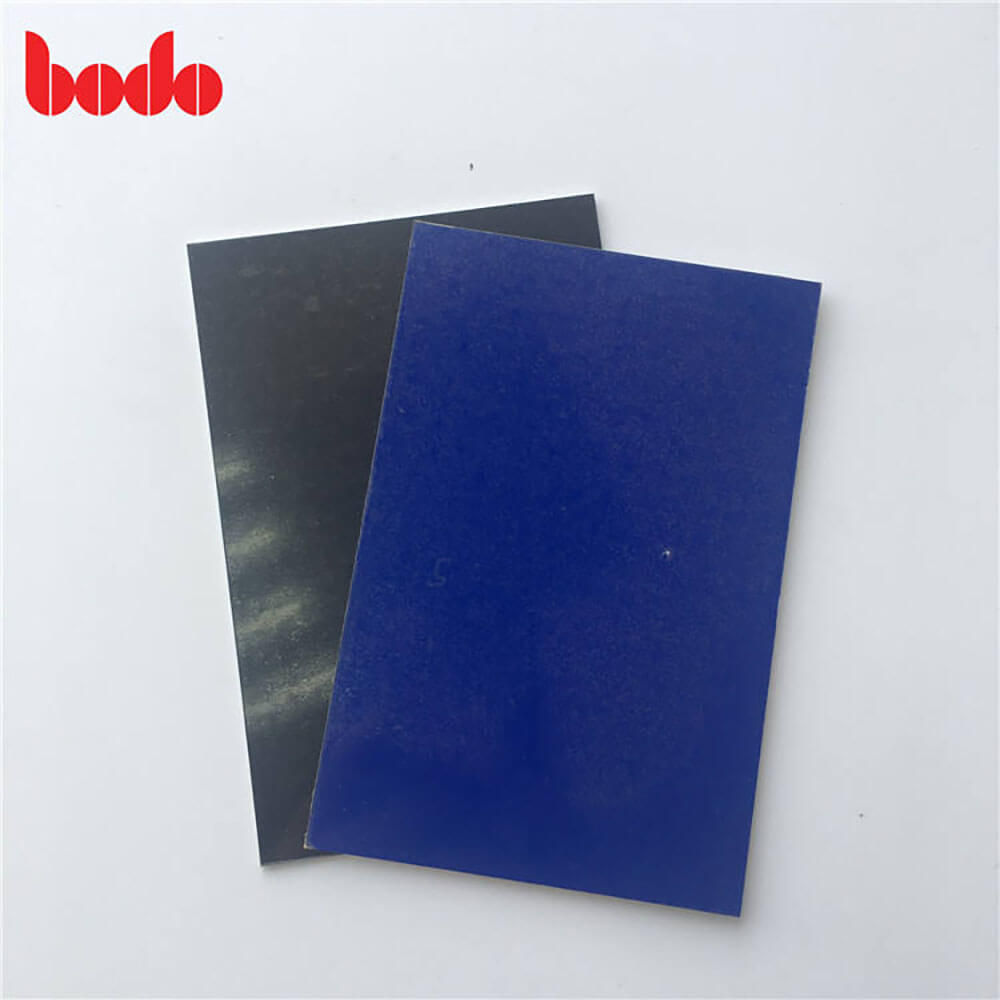

ABS plastic sheets are lightweight but robust, making them impact-resistant and able to withstand heavy loads. They are also rigid, which means they do not bend easily, making them ideal for applications that require stiffness and stability, such as automotive parts, toys, and electronic devices.

One of the most significant advantages of ABS plastic sheets is their resistance to chemicals, cracking, and heat. As a result, they are a popular choice for applications like automotive interior and exterior parts, appliances, and piping systems.

ABS plastic sheets are also easy to machine, mold, and fabricate, making them easy to process and adaptable for use in several applications. They can be cut, drilled, formed, and welded using various techniques, depending on the requirements of the particular application.

Moreover, one of the features that make ABS plastic sheets a popular choice for industrial manufacturing is its ability to be recycled. It is environmentally friendly and can be ground down and recycled to create new sheets, reducing the waste produced.

Overall, ABS plastic sheets are a versatile and durable material that provides a wide range of properties, making them an ideal choice for various industrial and manufacturing applications.